Subscribe to our systems or customize your own. Professional consultation with zero charge. Contact us

FMAS

Factory Monitoring & Analysis System

Design to elevate your business

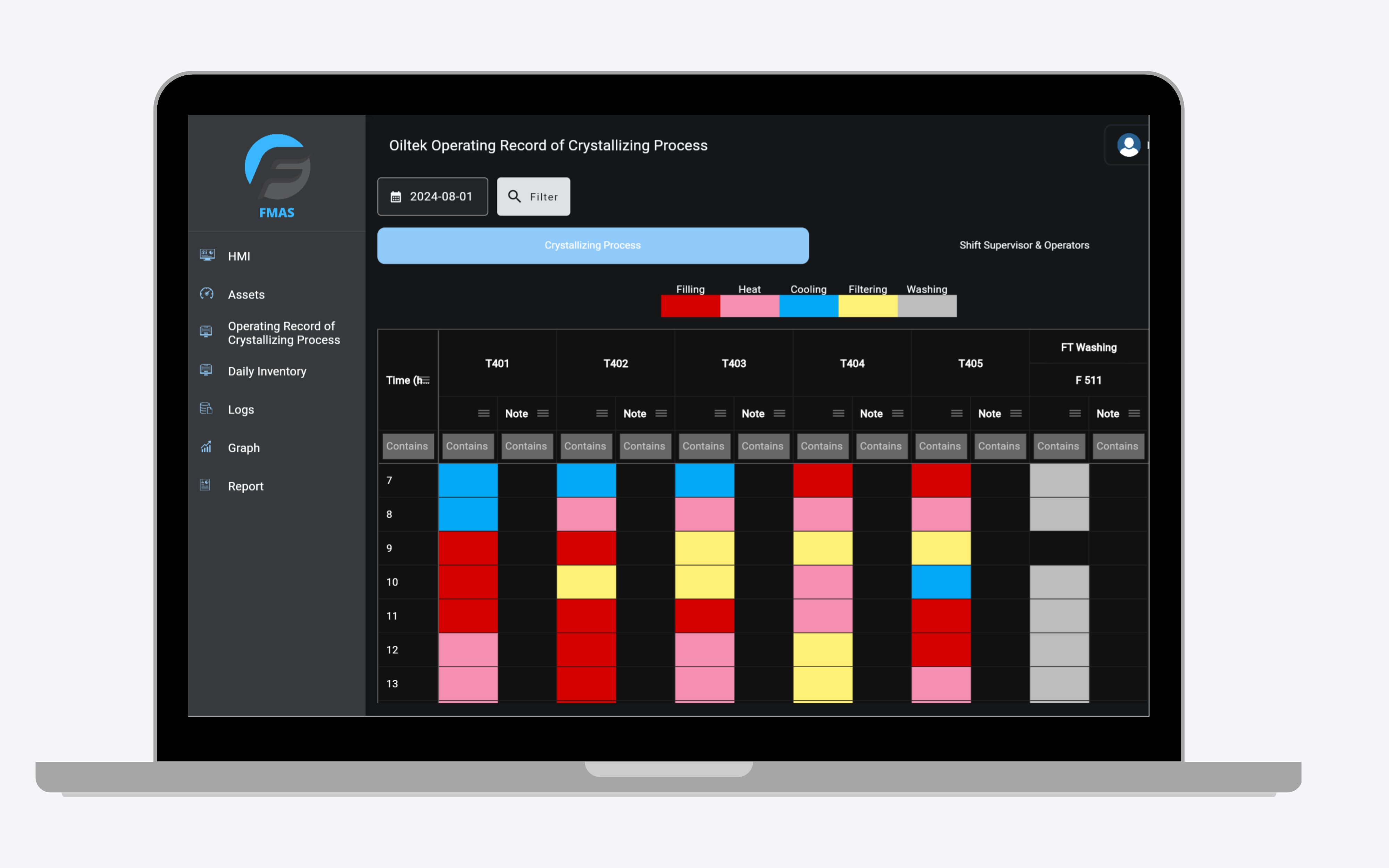

Daily Operation System

Designed to streamline and enhance the efficiency of daily manufacturing activities

Human Machine Interface (HMI) used in the context of an industrial process. visual diagrams showing how industrial equipment and processes are laid out, including the real-time parameters data such as temperature, pressure, water level and others relevant parameter.

Automatically inputs real-time data from SCADA into tables, ensuring seamless integration and accurate monitoring of operational parameters.

Export data retrieved from SCADA or manually inputted from tables to Excel. You can filter data based on date.

Production Monitoring System

Designed to automates the tracking of TEEP and OEE, machine utilization, and downtime to achieve peak production efficiency

Real-time dashboard form of visualization that automatically updates the important information.

TEEP combines OEE with utilization to provide a comprehensive view of how effectively your equipment is being used and how much potential there is to increase throughput with your existing assets.

OEE reveals how much of your Planned Production Time is truly productive.

Performance insight of specific production line, presenting essential metrics for evaluating and improving efficiency. You can filter data based on date and shift.

Downtime events are captured automatically but you also can create or edit manually.

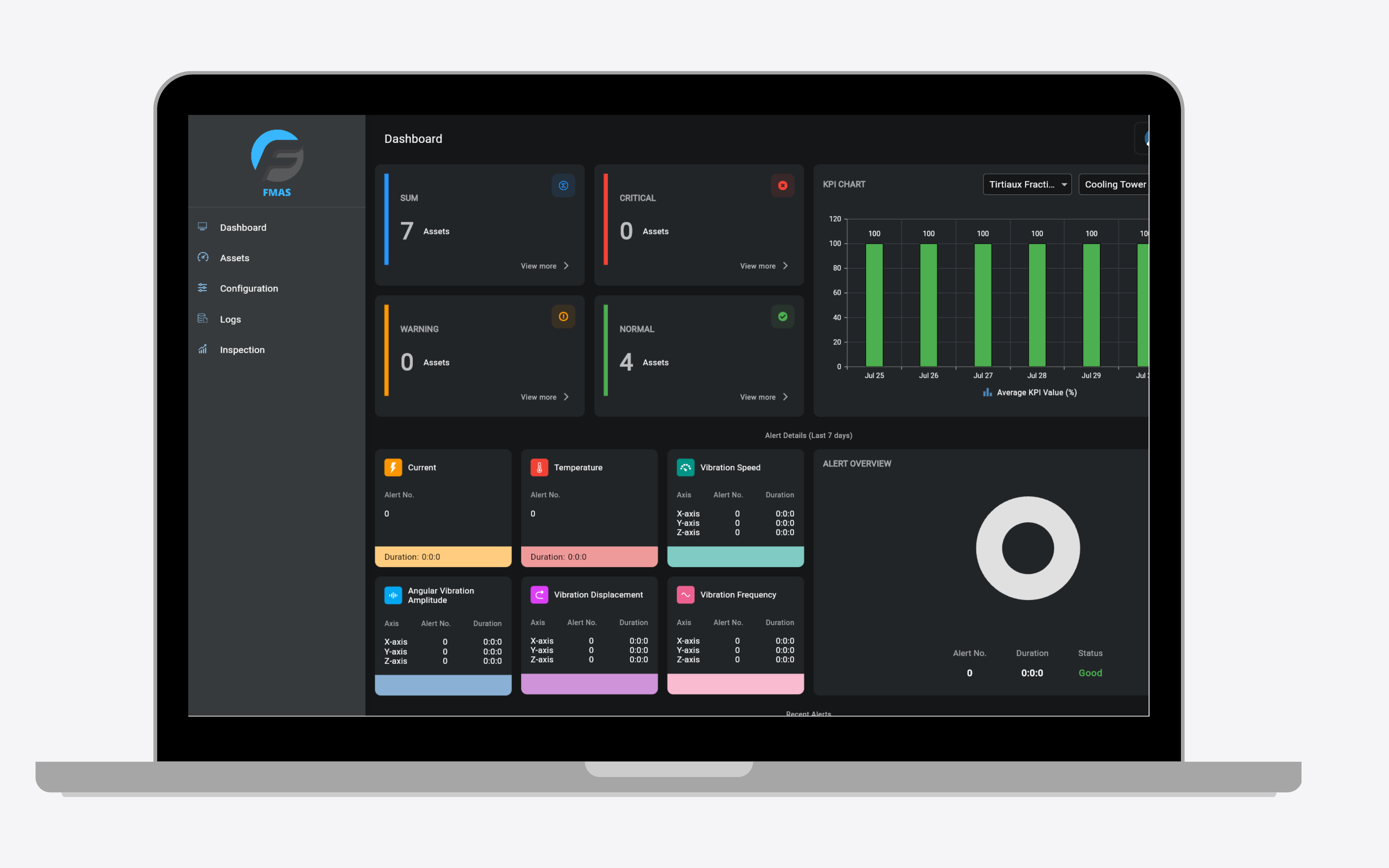

Predictive Maintenance System

Automates the monitoring of machine, such as vibration levels and temperature, to anticipate potential failures before it occurs.

Automates the monitoring of machine, such as vibration levels and temperature thresholds, to anticipate potential failures before it occurs. Integrate real-time sensor data and predictive algorithms to ensures continuous operation, minimizing costs and maximizing operational efficiency.

Provides detailed insights into individual assets, focusing on monitoring parameters and performance metrics to ensure optimal operational efficiency.

Modify the configuration settings of the respective asset. Provides immediate insight into whether the asset is being controlled automatically or manually.

Utility System

Automates real-time tracking of energy, water, and other utilities

Daily or monthly expenses related to energy usage, presenting various metrics and visualizations to help users understand and manage their energy costs effectively.

Provides an overview of the daily and current month’s energy consumption and insights into energy usage trends over the past six months.

Central for managing and create cost data related to organization’s operations.

You can select between two report types – collective or individual. Specify additional parameters such as line, assets, cost calculation requirements, and reporting period (daily or monthly).

Why FMAS is the best system for running your business?

Centralized Management

Offers a unified platform for managing activities across all departments, ensuring information is easily accessible within each user-friendly block.

Authority Levels

Customizable user authority levels ensure secure, role-specific access. Depending on your authority, certain system functions may be restricted.

Precise Auto-Input

Precisely inputs real-time data from SCADA and PLC into corresponding table columns based on predefined date/time settings.

Enhanced Monitoring

Provides real-time monitoring and reporting tools that help track performance, identify issues early, and make informed decisions.

Improved Coordination

By integrating various departmental functions, FMAS fosters better communication and collaboration across the organization.

Data-Driven Insights

The system collects and analyzes data to provide actionable insights, helping organizations optimize their processes and improve overall performance.